A mixed fleet of four autonomous mobile robots and two smart-forklifts works around the clock to improve material flows between the production line and storage.

Xingyu Auto Parts Co., Ltd. (abbreviation: Xingyu Auto) is a national high-tech enterprise specializing in research, development, manufacturing, and sales of auto parts. Products are primarily used for supporting international and domestic passenger vehicles and commercial vehicles. It currently develops and produces components for mid-to-high-end and large commercial vehicles. Under the trend of intelligent manufacturing, Xingyu Auto hopes to introduce a flexible and intelligent logistics system to open up the entire process operations from raw material warehousing, outbound picking, production line material distribution, and finished product storage to reduce costs and increase efficiency and stay competitive in a fast-changing market.

To achieve these goals, Xingyu Auto is seeking a flexible, autonomous, traceable, adaptable, and scalable system that could operate on a 24/7 schedule and automatically connect the storage area with the production area. Furthermore, the company required a system that works on AMRs and smart-forklifts under the same roof since much of the material needs to be transported by both carts and pallets.

Mixed autonomous fleet to maximize the result

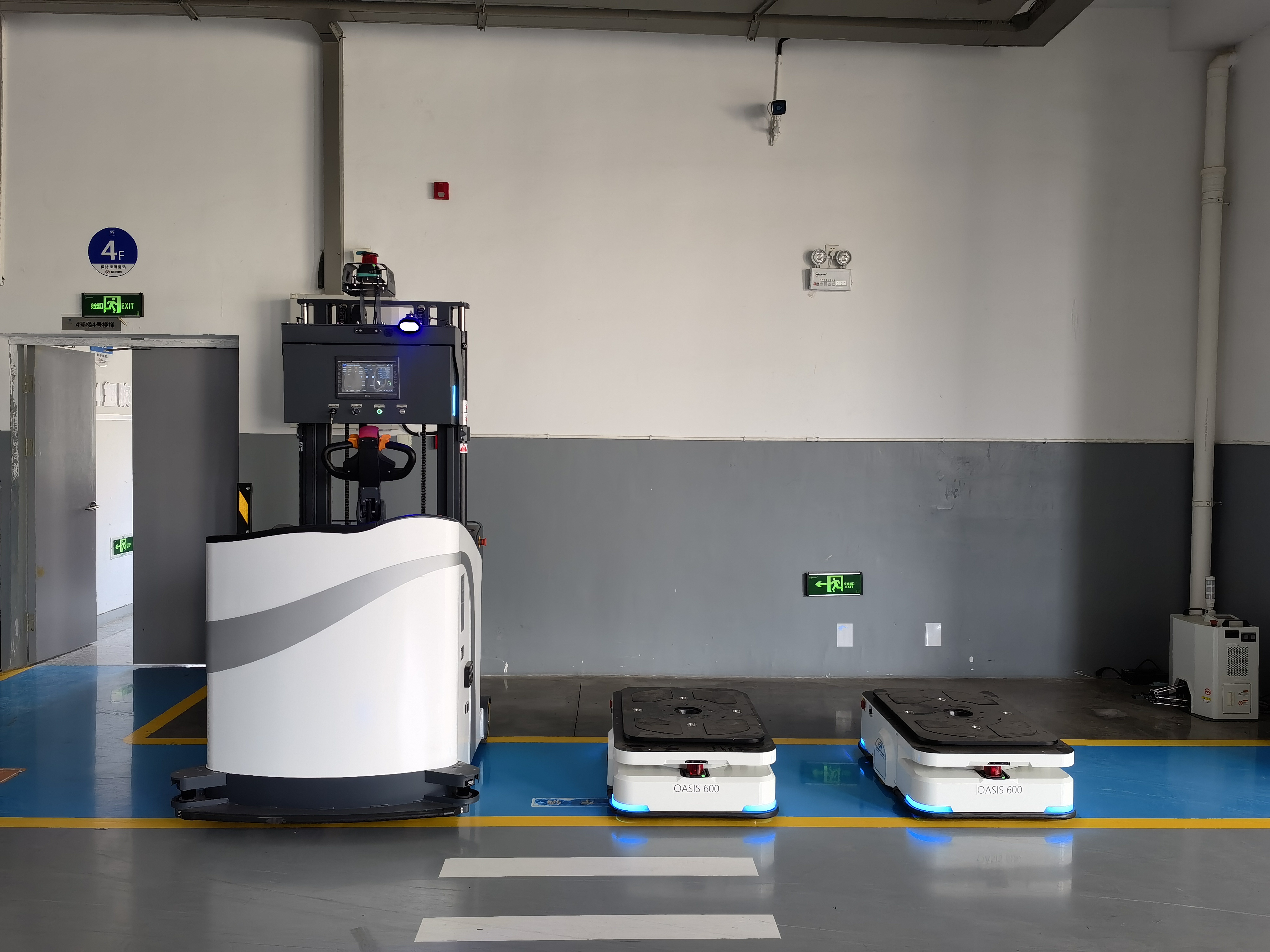

Xingyu Auto chose to deploy a fleet of four Oasis 600UL robots and two Gulf 1500 smart forklifts from Standard Robots, the industry-leading AMR provider. The goal of these autonomous mobile robots was to improve and enhance the autonomy of internal logistics, collaborate with workers to create a safer working environment, and increase efficiency while tracking material delivery.

In the same scenario, the autonomous forklifts and AMRs using laser SLAM navigation can create maps independently and realize the mixed operation of multiple vehicles under the same map through FMS. Also, AMR can autonomously avoid obstacles in complex environments, with a positioning accuracy of millimeters.

The scope of operations covers the production workshop, raw material warehouse, and finished product storage, including stacking, sorting, distribution of raw materials, finished product distribution, storage, and other process involving cross-floor handling. In addition, the integration between the robot scheduling system FMS and the warehouse management system WMS is a crucial feature of the flexible solution. As a result, the whole production line is seamlessly connected to meet the needs of Xingyu Auto's intelligent material handling and lean production management.

Multi-vehicle cooperation, multi-level protection, multi-system interconnection safe, flexible, and stable

The Gulf smart forklifts have a payload of 1500kg, which takes the pallets from the warehouse and places them on the customized material cart transported by the Oasis 600UL AMR with a lifting module. Then, the AMR transports the materials to the production line to realize a connecting operation of the autonomous material handling.

Safe operation alongside people in dynamic environments was one of the main reasons that Xingyu Auto invested in mobile robots and forklifts. All robots are equipped with lidar, 3D vision sensor, safety edge, proximity sensor, etc. They can detect low-hanging objects or floor obstacles in a three-dimensionally manner to ensure production safety.

While the safety of the operations was crucial to our client, it was also essential to have a simple setup and user-friendly software so the ROI could be delivered as promised. As a result, the robot scheduling system FMS and WMS are harmoniously connected, and the ability to perform precision docking between AMR and various automation equipment such as vertical warehouse shelves and robotic arms operated production lines and complete the unified scheduling of resources.

After introducing the Standard Robots intelligent logistics solution in the Xingyu auto parts production workshop, the efficiency and quality of the production logistics in the plant have been significantly improved. In addition to continuing to provide customers with more advanced AMR products, Standard Robots is also committed to the flexible interconnection of different process equipment in the factory at the logistics level to respond to the needs of customers in the auto parts industry with more accurate, efficient, and safer solutions.