Japan-based Trusco Nakayama Corporation is a specialized trading company that supports Japan's manufacturing industry with an inventory of machine tools unlike any other in the country. Committed to serving customers with fast and reliable delivery, the distribution centre in the greater Tokyo area operates on a 24/7 schedule. The Oasis 600C automated pallet transports between the palletizing station and the outgoing dock. This first development phase will be repeated throughout the facility to reduce logistics downtime and enable 24-hour operations while improving outbound efficiency and worker safety.

Adaptable mobile robot for a safer and more efficient palletizing station

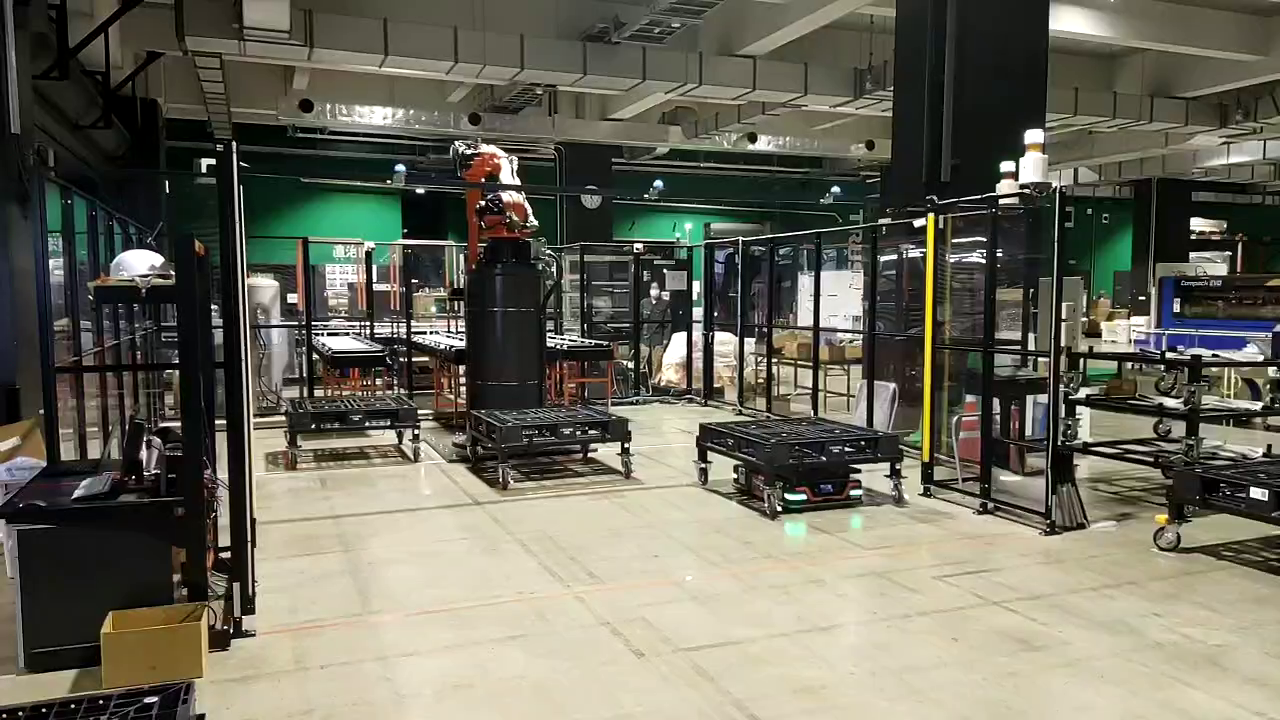

At Trusco Distribution Center, state-of-art technologies have been implemented since day one, a primarily solar-powered logistics center that ran by less than 100 employees with complete digitalized resource management systems. In addition, replacing AGVs with autonomous mobile robots (AMR) will make a lot more sense when the objective is intelligent logistics. In another world, intralogistics 4.0

Every two Oasis 600C-SRL robots are part of one fully automated palletizing station that includes a six-axis robot to pick goods from each of three roller conveyors autonomously and load the goods directly onto three pallets, which the 600C will transport the full-load roller pallet and move to the outbound loading dock. The other 600C will be ready with an empty pallet to keep the palletizing station going. This enables Trusco to eliminate traffic around the palletizing station and loading dock, replacing manual tasks with safe, collaborative mobile robots.

Leveraging advanced safety features and supporting system integration.

The Oasis 600C has a payload capacity of 600kg, which was one of the reasons Trusco selected this specific robot. However, a heavy-load robot driving autonomously among humans is a critical factor that challenges the deployment. Besides the new generation dual diagonal radar and 360° obstacle sensors, the robot also uses sound and visual signals to notify people in the surrounding environment when it operates while pauses or attempts to move around obstacles.

As stated that safety is one of the reasons that got the 600C selected by Trusco, it was also important that the robot control system has to be easy to use while integrating with the existing operating software. Therefore, the self-developed Fleet Management System enables the company to start benefits immediately since it is based on SLAM navigation without aiding infrastructures or abandoning the existing software. Moreover, it intuitively benefits the employees by easy to map and program.

Established a future-ready solution for expansion

The first deployment phase is primarily focused on the new line of the palletizing station and set out to be the measure for the future AMR automation solution in the facility for other internal logistics lines. With a fleet of Oasis mobile robots assisting in a dynamic, highly efficient logistics center where each 600C can go where it is required when it is needed to maintain production flowing, especially in the multi-floor warehouse. However, without sharing too much detail about their next deployment phases, all partners firmly believe Trusco Nakayama is in a strong position for further intralogistics 4.0 using intelligent technologies.