To increase productivity and lower operating costs, this automotive OME (Original Equipment Manufacturer) factory in the Greater Bay Area of South China has upgraded from manual material transport to automatic delivery using autonomous mobile robots from Standard Robots. 8 Oasis 1200D robots, all equipped with an automatic drawing module, towing material and empty carts between the production line, the warehouse, and the assembly line, contributing to the automation of internal logistics, reducing operating costs and increasing overall productivity.

Solution

The manufacturer has been producing vehicles' components and assembling cars directly for the enormous Chinese automobile market for decades. But, for the last few years, the company has concerns over internal transport costs and long-term competitiveness due to labor shortages and rising labor costs. Often, automotive industry automation is done by old-style AGVs with fixed track and trolley. But after reviewing offers available on the market, the Autonomous Mobile Robot stands out pretty quickly, won by the flexibility, fast deployment, large capacity, and safety features.

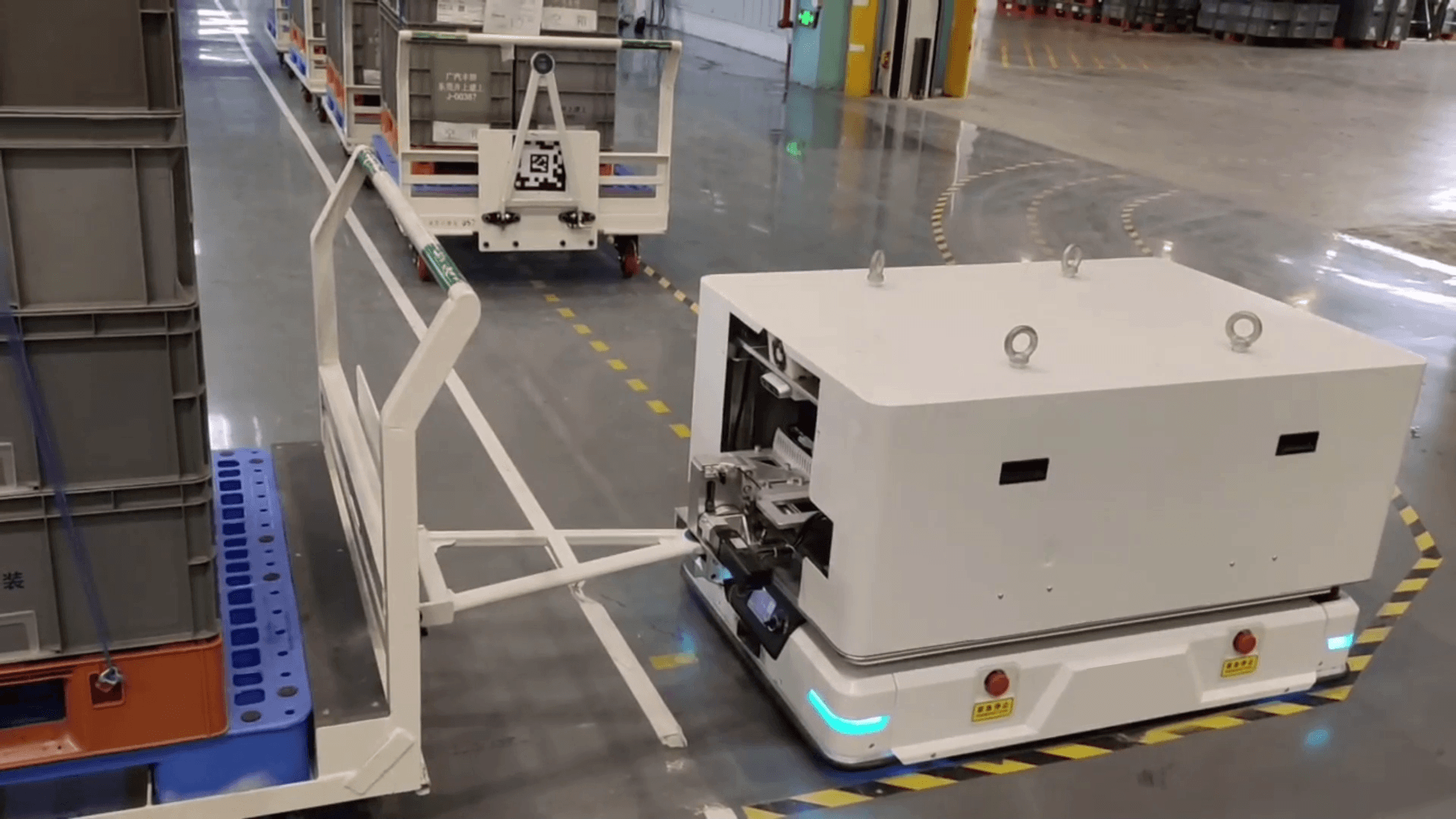

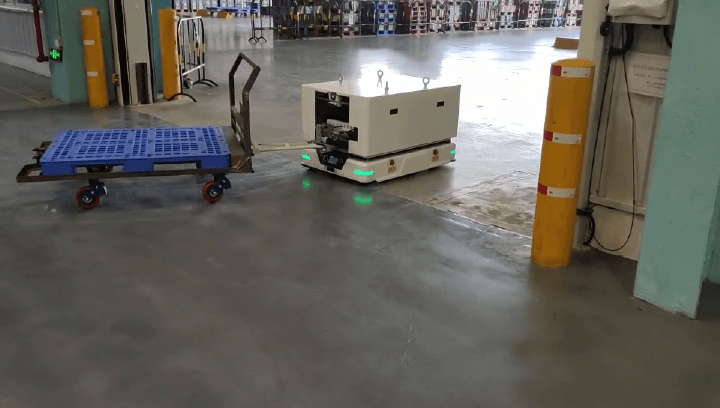

The automation solution was to streamline production processes, automatic towing martials carts, reduce error rates, and work within the existing physical environment. The Oasis 1200D with a top-mounted SRD module was designed to automate large-sized internal transport of carts and heavy-load containers with a capacity of up to 1.2 tons and massive torque. The mobile robots and customized carts have been deployed into production since early 2021.

Organizes The Entire Manufacturing Process

At this car manufacturing facility, there are 12 workers who load and stack materials into containers on wheel carts from the production line and transport them to the next assembly line by driving manually. These jobs are repetitive and physically demanding, making it difficult to retain long-term workers. Also, there are safety and wear and tear concerns about manual driving on the production floor with corners and gates that leaking clear vision.

The Oasis 1200D uses laser SLAM technology and visual camera for the autonomous towbar can now fully automated logistic parts of the production hall. Workers can return their focus on loading materials and finished parts directly onto the Oasis 1200D, which is equipped with an Oasis draw module. The robot transports the finished parts into assembly line holding area when the loading process is complete. The present of mobile robots allows production hall, warehouse, and assembly line be more efficient, cleaner and safer.

Efficient and Integratable Fleet Management System

Standard Robots FMS (Fleet Management System) software forwards the management of the robot fleet, in terms of basic setup, mapping out the operation area and programming tasks. In this case, the AMR solution needs several parking spaces at the staging area and at each end. The FMS automatic detects empty space from the last robot task and facilitates each robot to park accordingly. The same rules apply to the 3 automatic charging stations. The existing MES (Manufacturing Execution System) from the manufacturer was integrated with Standard Robots FMS, which requires less communication time and simultaneously manages missions, coordinates robot movement, and monitors schedules and changes.

An Eye To The Future

The robots maintain delivery time schedules without any delays, resulting in the entire manufacturing process becoming smooth and easily controllable. "The changes are obvious, and it was quite noticeable after implemented 8 AMRs," said the Operation Manager. The speed of internal logistics processes has significantly increased, the production hall has become more organized, and safety-related issues have been eliminated.

All these possible benefits mentioned above are pieces of the smart manufacturing puzzle. Companies like our clients that grow and evolve with an eye to the future will see that investing in AMR is necessary to become economically competitive.