Semiconductor manufacturers often face the challenging task of developing new and more effective methods to automate the handling of their wafers. The wafers come in various forms and sizes, requiring distinct handling techniques, which can make determining a suitable handling solution a time-consuming and costly process for manufacturers.

Standard Robots can help in this area. Our proven experience and comprehensive understanding of wafer handling automation and factory integration capabilities enable us to create wafer handling equipment that meets all of your project requirements, whether it involves resolving a complicated wafer handling scenario or integrating automation into your existing process device.

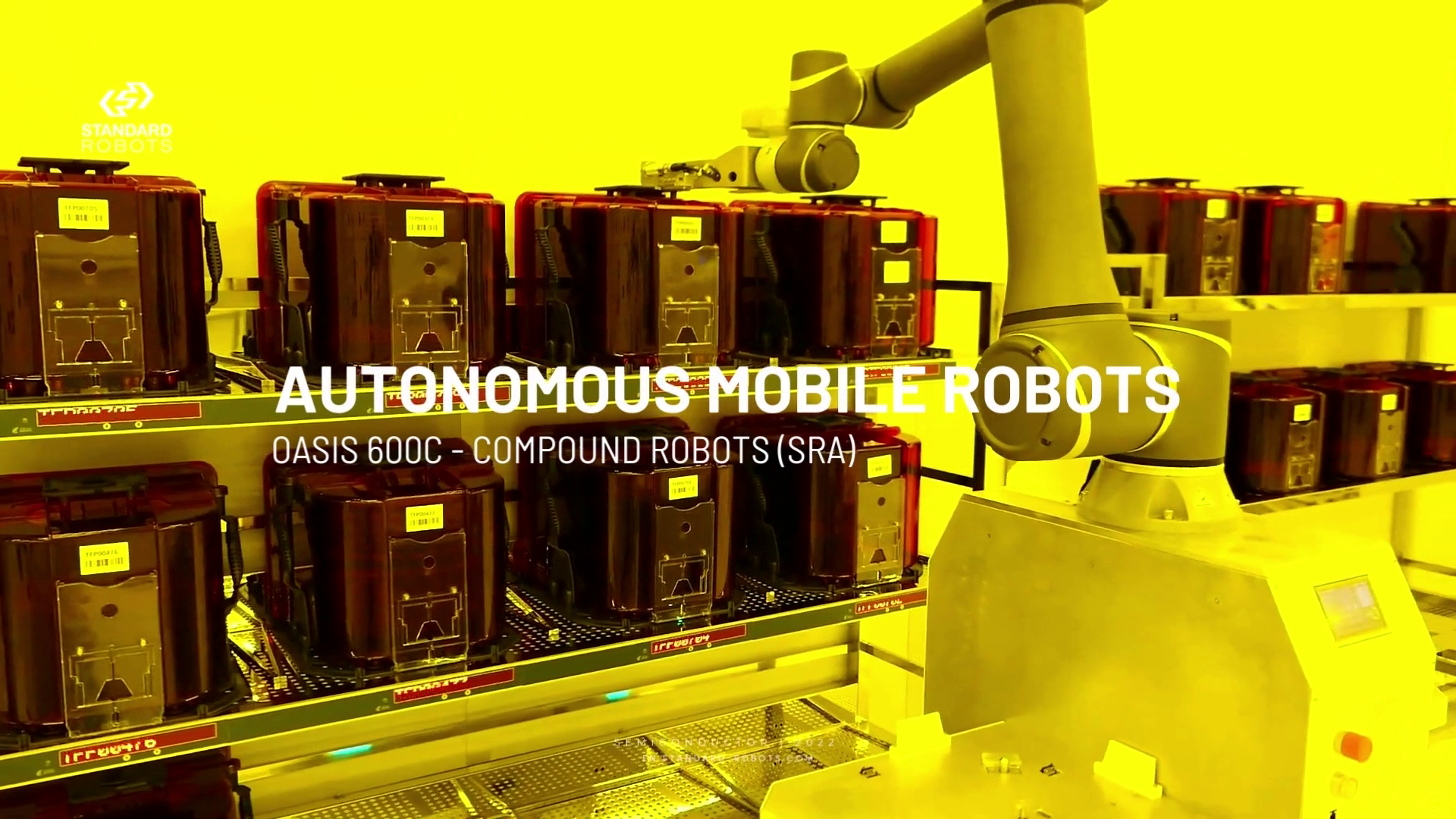

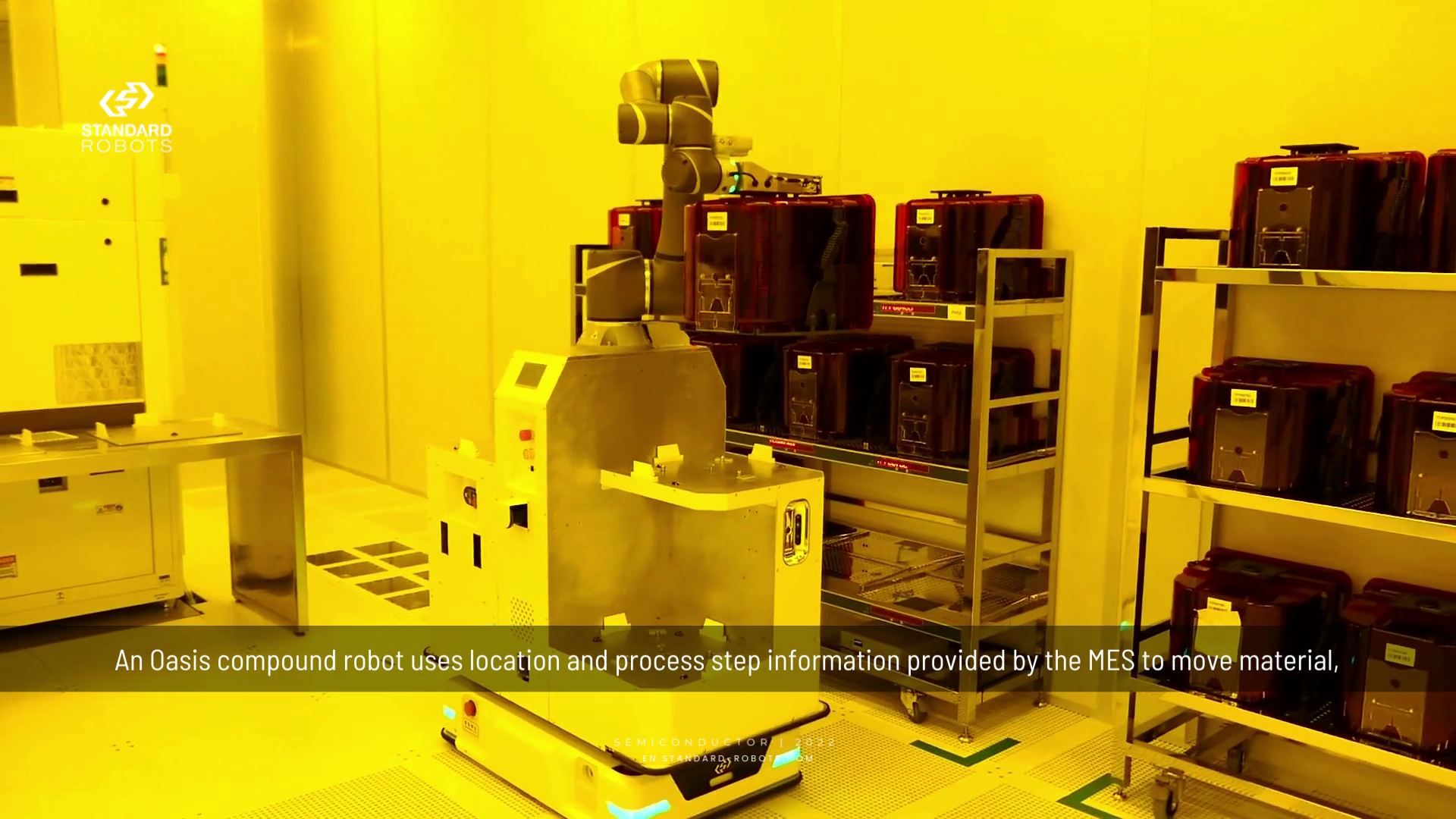

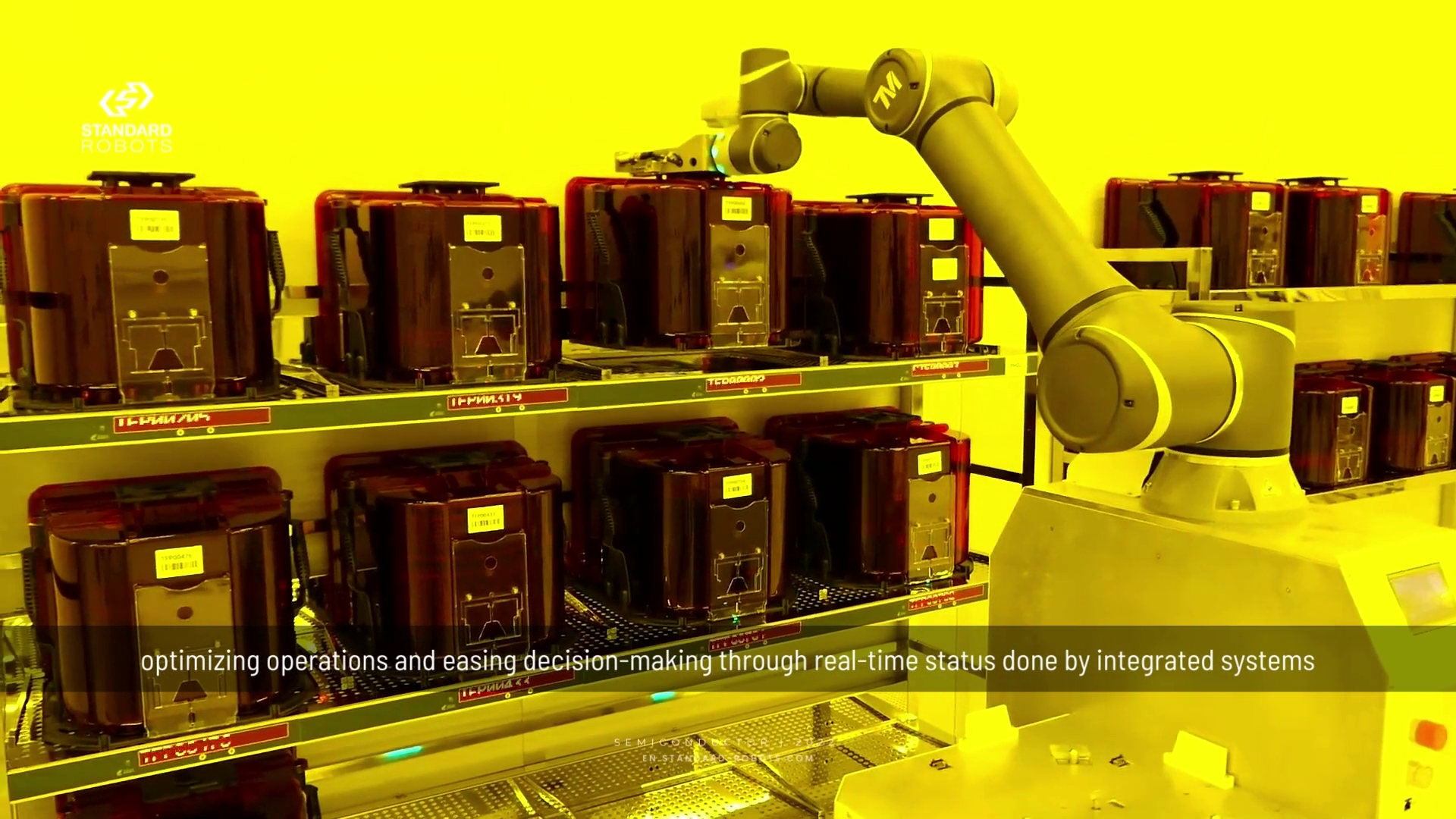

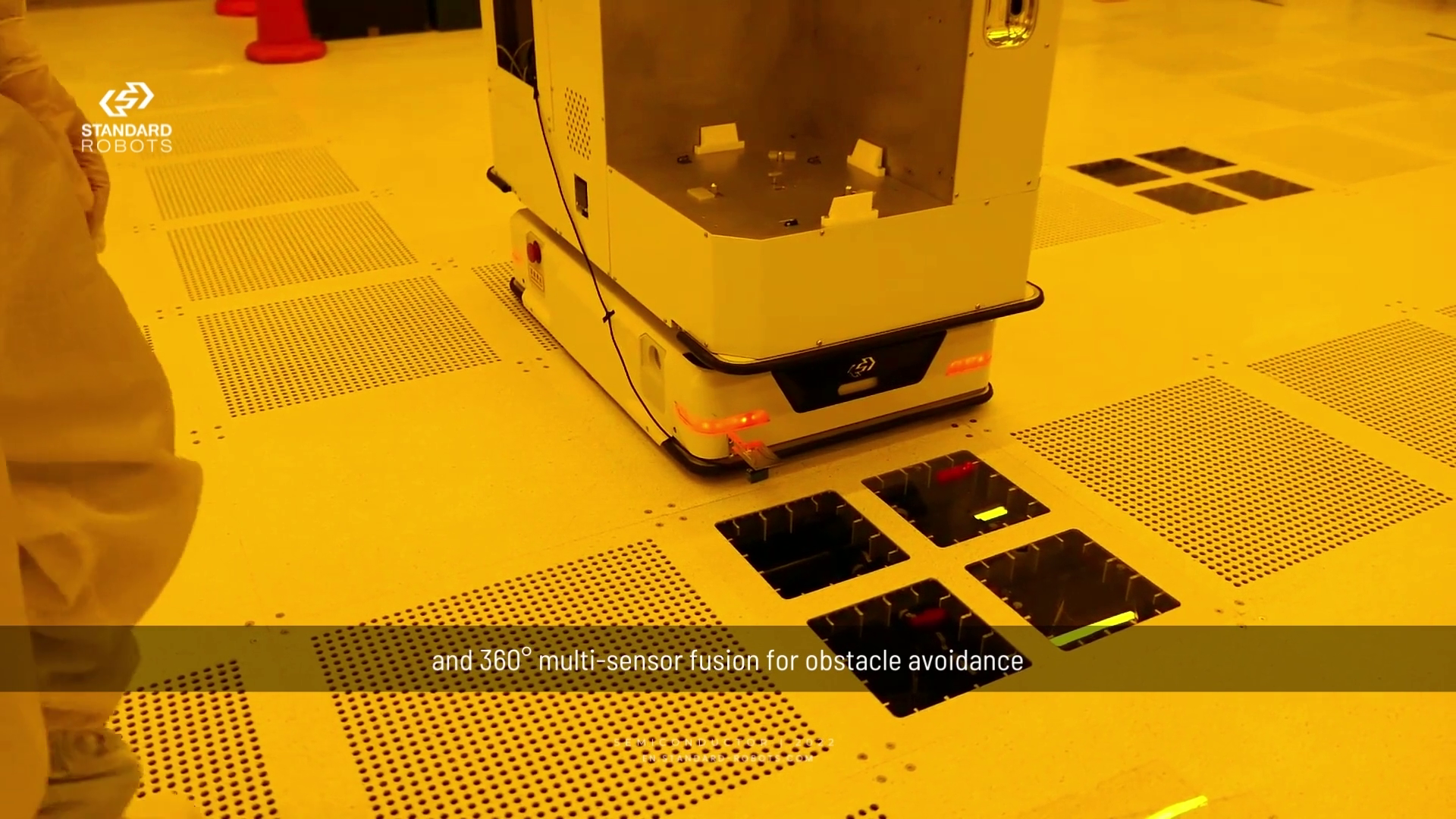

This is a flexible distribution solution for materials in a semiconductor processing facility. The wafers are packed into FOUPs (known as Front Opening Universal Pods) and distributed to each workstation for processing. The AMR handles the identification, routing independently, and delivery of materials to the associated process equipment, and places and removes the FOUPs from the load ports. To ease any processing bottlenecks, an intelligent storage rack has been designed to hold processed wafers and monitor flows to accomplish dynamic intelligent distribution.

Optimizing operations and easing decision-making through real-time communication done by integrated MES, FMS, and WMS.