As a leading global car seat manufacturer, Dongfeng Lear has established extensive partnerships with major domestic mainstream car brands in China, consistently ranking at the forefront of the industry in terms of sales scale. In recent years, Dongfeng Lear has been focused on constructing an intelligent car seat factory. Since 2021, Standard Robots has worked alongside Dongfeng Lear to create smart manufacturing facilities featuring flexible logistics solutions. This collaboration has produced a highly successful model for domestically produced, intelligent car seat manufacturing, and serves as a pilot concept for similar manufacturer.

Wang Yongkun, CEO of Standard Robots, led a team to Wuhan Dongfeng Lear to conduct a return visit for key customers. Han Ying, the factory's General Manager, warmly welcomed them and stated, "On one hand, the AMRs have contributed to a more rational factory logistics layout and have increased the flow rate of materials, ultimately improving overall productivity. On the other hand, through the implementation of flexible logistics solutions, we have been able to effectively alleviate inventory pressure and significantly reduce management costs."

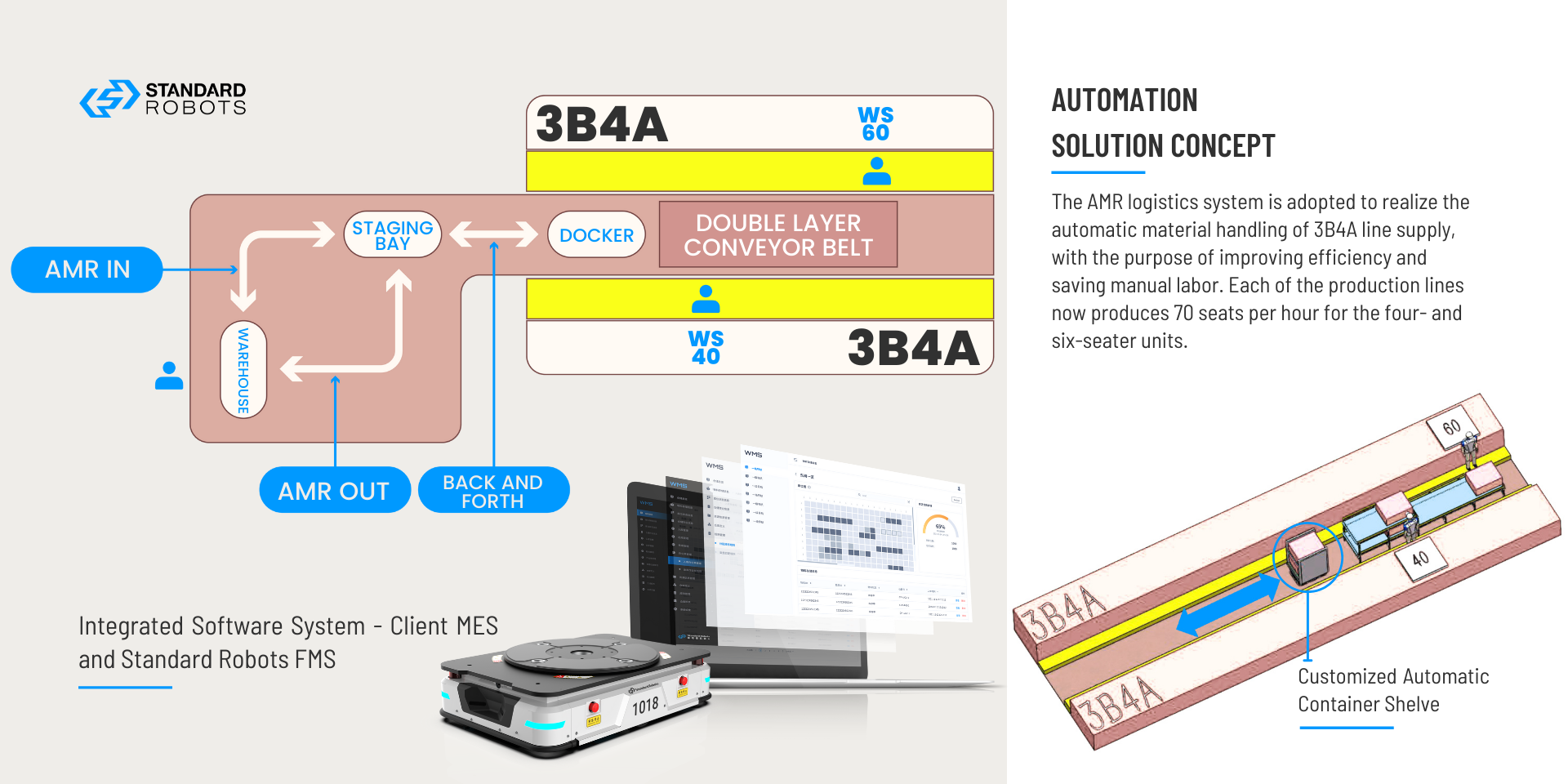

The initial trial solution was developed for production line 3B4A, which was designed to automatically feed materials to workstations 40 and 60. The objective was to improve efficiency, strengthen the lean principle, and reduce manual labor. As the demo solution proved capable of meeting the requirements, the same concept was extended to almost 100 Oasis AMRs, covering the entire factory floor.

Wang Yongkun also commented, "Working with a global leader in the automotive industry is a great pleasure, and this valuable experience will benefit our future industrial automation solutions. This project aligns with our company's goals of creating safer, more efficient, and flexible AMRs, as well as better solutions."