Xiaomi SU7 has garnered widespread attention and captured the hearts of the youth with its innovative design and affordable prices, receiving over 90,000 orders within just 24 hours of its market debut.

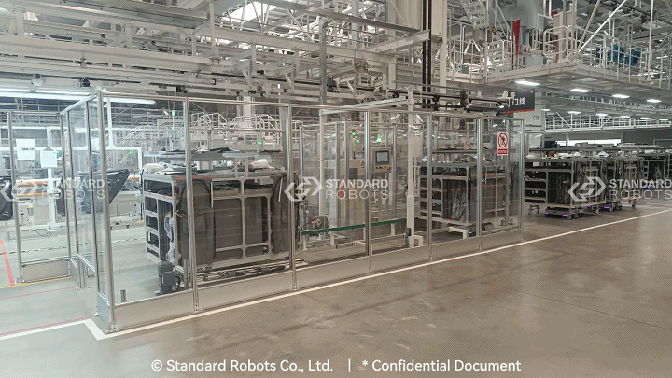

A large number of orders implies significant production pressure that factory may withstand. Anticipating this, Xiaomi has partnered with Standard Robots to build final assembly line with 100% Laser SLAM (Simultaneous Locating and Mapping) AMR in their smart factory. The alliance couples Standard Robots' AMR fleet with its' customized turn-key solution, improved internal logistics efficiency and guaranteed safety in the workshop.

Proved by abundant projects from top-tier brand such as BYD, NIO, TOYOTA, and Volkswagen, Standard Robots offers mature one-stop solutions for Xiaomi smart factory, ensuring rapid project delivery and seamless integration.

Over 200 AMRs, including Oasis 300E, Oasis 600E, and Oasis 1200E, have been deployed on the final assembly line to meet different requirements for quick material feeding. Furthermore, flexible modular design enables Standard Robots’ to easily accommodate various carriers and customized add-on modules for transporting multiple materials such as door, exterior trim, dashboard, and more.

High-frequency human-machine collaboration is a common occurrence in the scene of Door SPS (Set Parts System). Consequently, the Oasis 600E SRL AMRs are required to decelerate to a complete stop when entering this complex environment, ensuring that workers have enough time to safely cooperate with the AMRs. Once they receive completion signal from the workers, the AMRs will proceed to subsequent areas, where the customized carriers will then automatically feed materials into the production line.

Furthermore, supported by the robot control system, Standard Robots’ AMR fleet can easily handle the frequent and voluminous transport of materials and automatically detect whether storage positions are occupied, thereby avoiding traffic issues and achieving dynamic dispatching and position alignment. These capabilities further enhance the efficiency and safety of operations. In addition to the features mentioned above, our AMRs perfectly fulfill Xiaomi’s requirement that production capabilities need to reach 50 Jobs Per Hour (JPH).

Apart from AMR fleet, Standard Robots’ RIoT platform also plays a key role. The platform has accessed factory’s own systems, covered an area of nearly 70,000 square meters and 100 processes in the factory, and communicated with over 200 third-party vehicles and various factory facilities, helping the AMR fleet achieve agile dispatching and self-adaption in diversified environments.

As a newcomer in the new energy automotive industry, it is important to establish a solid reputation and foster consumer trust through distinctive product quality and advantages. By partnering with Standard Robots, Xiaomi factory has not only improved its production efficiency but also effectively tackled labor shortages. This achievement has positioned it as the final assembly line in China to 100% deploy SLAM AMR. Consequently, Xiaomi’s experience offers a compelling reference for businesses looking to automate their manufacturing processes.

About Xiaomi

Xiaomi, a leading technology company renowned for its innovative consumer electronics, enters the electronic vehicle industry with its debut model, the Xiaomi SU7. Xiaomi SU7 are designed with a focus on performance, intelligent connectivity, and user-centric design, aiming to provide a seamless and eco-friendly driving experience.