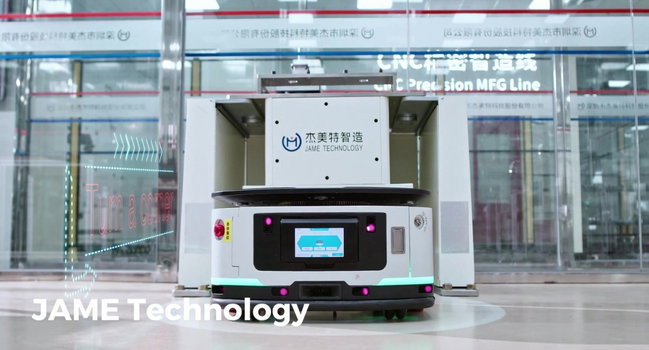

The Oasis 300 series AMR at JAME Technology in Dongguan, China is equipped with SRT top-mount conveyor module and to help achieve fully automated unmanned manufacturing processes by automating the internal transportation of materials throughout the facility. Bring consistency and flexibility to the workflows of intelligent manufacturing.

The Oasis 300 series AMR at JAME Technology in Dongguan, China is equipped with SRT top-mount conveyor module and to help achieve fully automated unmanned manufacturing processes by automating the internal transportation of materials throughout the facility. Bring consistency and flexibility to the workflows of intelligent manufacturing.

Solution

JAME is a comprehensive high-tech development enterprise integrating R&D, manufacturing, sales, and service, with more than 200 employees and is famous for mobile intelligent terminal accessories manufacturing in China. The innovating and open-minded enterprise concept has let JAME realize a new leap from traditional manufacturing to intelligent manufacturing, allowing it to maintain industry leadership with strong international competitiveness and continue its close cooperation with the world’s top 500 companies.

The company new smart plant uses automated machines and robotics extensively in its production, which includes the CMM Precision Measurement Line, CNC and EDM precision MFG lines, and Smart Electrode Storage Units. The automation task was a bit complicated due to transporting different materials between multiple production lines and the warehouse, which involves docking stations of various sizes and shapes.

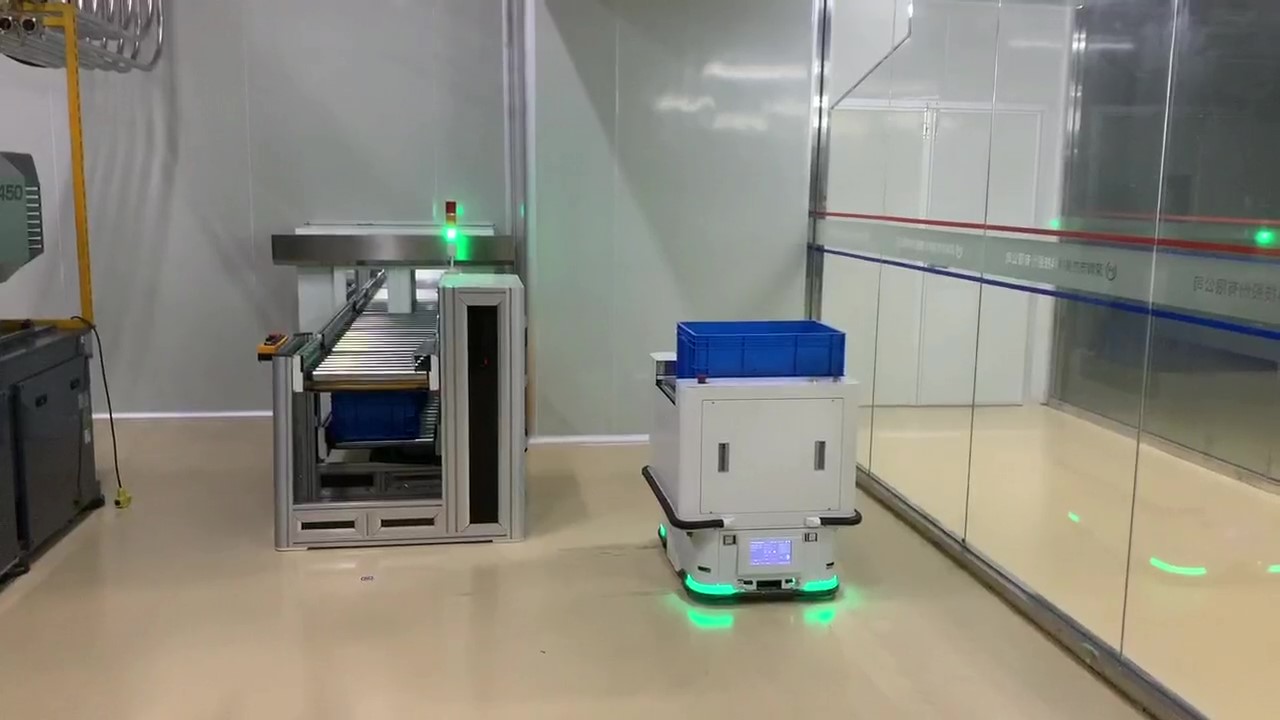

In addition, JAME requires the ability to adapt to high-frequency and changeable production patterns that match the new product designs' frequency. So, the company needs an internal logistics automation solution that is not fixed, able to communicate with all third-party equipment and systems, and capable of navigating autonomously in a lights-out, 72-hour unmanned production facility. The mission quickly falls on Oasis 300UL-SRT, AMRs equipped with STR conveyor modules, and 300C-SRL, with a customized top-mounted tray to handle raw material transport. Also, a Fleet Management System that allows robots to open doors, air showers, automatic recharge, and traffic control.

In a constituent changing industry, flexibility means efficiency, cost-saving, and fast payback.

The Oasis autonomous mobile robots (AMR) customizable module is the key factor that made Standard Robots flexible solution very appealing to our clients. The SRT module is a top-mounted conveyor that is designed to optimize material transport by loading and unloading crates at a single stop with an automated docking station. The FMS allows the robots and third-part docking stations to operate under the same software and is supported by one algorithm that achieves fully automated logistics workflow.

The Standard Robots conveyor solution for JAME's smart factory was completed quickly and easily thanks to the simplicity of the implementation of the Oasis AMR. Different from the traditional AGVs, the Oasis AMR does not need pre-installed infrastructure to help it navigate. The radar SLAM technology makes the 300UL adapt in real time to the immediate surroundings and is free from predefined routes. The SRT conveyor module also includes multiple sensors to aid in the precise connection with the serval docking station and other material crates handling tasks.

Other Oasis 300C robots with customer-made raw material trays on the SR-lifting modules are in the same facility to transport items between storage to the CMM precision measurement workshop and CNC & EDM precision MFG line. This Oasis 300C automated workflow can be changed several times in a short production period and often requires the robot to go through automatic doors and dust-free air shower units. Therefore, using mobile robots and integratable FMS for JAME's new smart factory project seems like an obvious choice.

Investing in the long-term

One of the key reasons that holds companies from investing in new technology is how cost-prohibitive it appears to be. Rising inflation, energy costs, and higher wages are crashing manufacturers’ cost margins and constraining their ability to try new technology. However, AMR automation is a critical solution to reduce costs and magnify profitability over the long term.

Standard Robots normally achieve ROI in 15 months or less, helping companies turn investment into long-term sustainable growth. Furthermore, the Oasis mobile robots do have a wide range of module options for performing different tasks or simply reprogramming them to have that versatility tag on your company profile. With all the benefits mentioned, JAME Tech intends to continue with the implementation of autonomous mobile robots in its new smart factory and expand flexible solutions to one other location.