As spring ushers in new growth, manufacturing floors evolve alongside seasonal shifts, demanding adaptive technologies to keep operations smooth amid environmental changes. In the fast-growing new energy sector, from power battery production to photovoltaic module assembly, manufacturers face fluctuating demands for precision and safety. Standard Robots, renowned among transportation robot manufacturers, steps into this dynamic scene with functional robot solutions crafted to manage heavy loads and delicate materials seamlessly. Their functional robot service bridges the gap between complex manual tasks and fully automated workflows, offering manufacturers a reliable way to meet rising production challenges with intelligent material handling robot solutions tailored for the new energy industry’s unique environment.

The challenges of transporting heavy and delicate materials in new energy manufacturing call for robust yet precise robotic solutions. Standard Robots’ differential drive back-carrying robots stand out in this field, carrying loads ranging from hundreds of kilograms to over a ton, demonstrating the expertise expected of seasoned material handling robot manufacturers. These robots efficiently shuttle materials such as electrode coils and batteries across sprawling factory floors with dust-proof and corrosion-resistant designs, perfectly aligning with stringent environmental requirements. Their multi-sensor fusion technology enables real-time obstacle detection and dynamic path corrections, maintaining safety and workflow continuity. By integrating with plant management systems, these robots not only transport goods but also enhance scheduling and supply chain transparency. As functional robot manufacturers, Standard Robots crafts each unit to navigate complex spaces while minimizing manual lifting, reducing workplace strain and improving operational safety. This combination of durability, precision, and adaptability exemplifies progressive functional robot service aimed at sustainable, efficient manufacturing in evolving production settings.

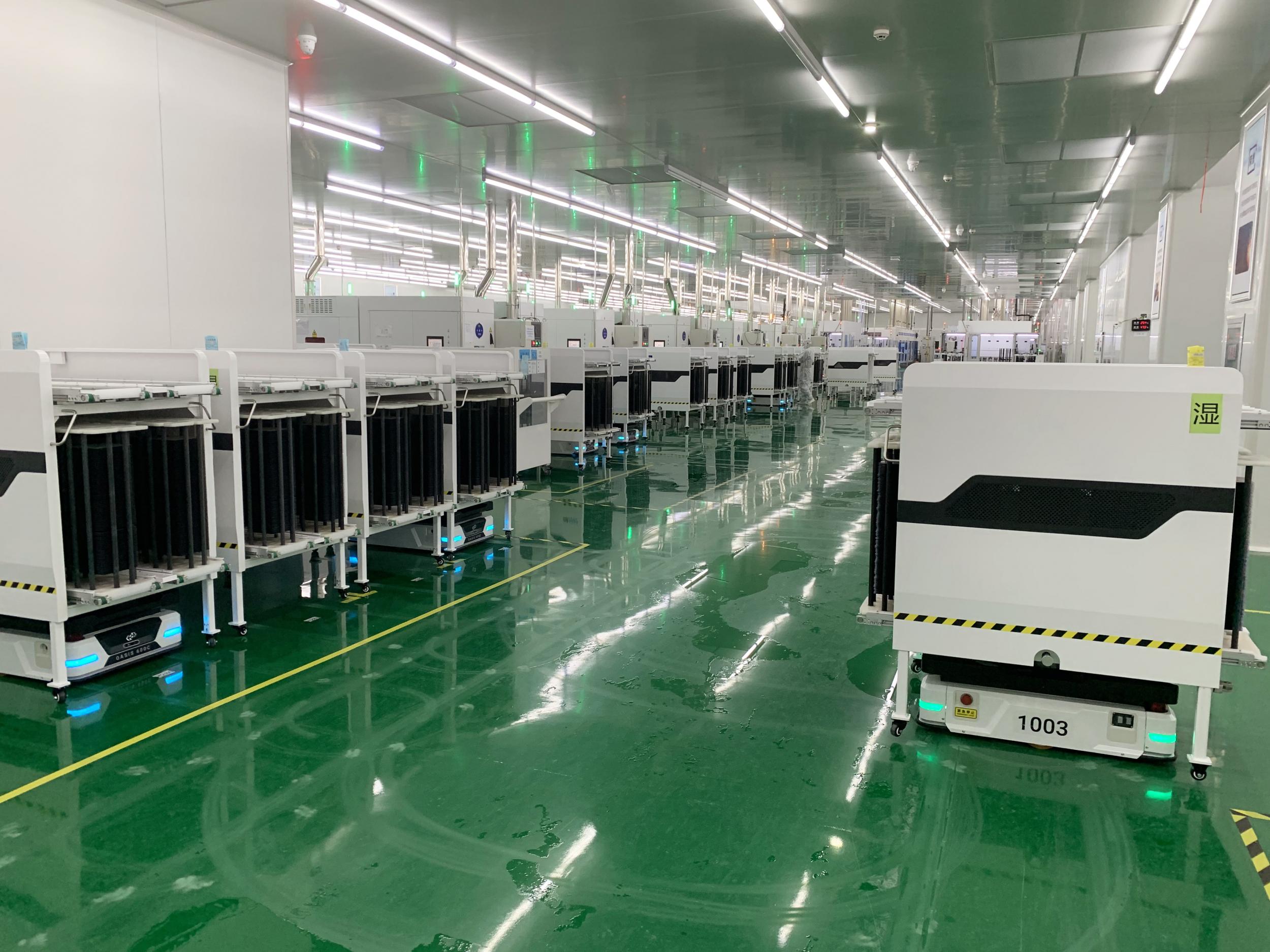

Seamless coordination between robots and plant equipment is vital for efficiency in new energy manufacturing, where varying process steps require synchronized action. Standard Robots, recognized among leading transportation robot manufacturers, offers material handling robot solutions that connect functional robots directly to existing plant systems, enabling fully automated material flows. Such integration ensures that raw materials, intermediates, and finished products move smoothly without manual intervention, reducing error rates and downtime. Utilizing proprietary control platforms and multi-algorithm fusion, Standard Robots facilitates communication between production lines and logistics robots, creating a synchronized manufacturing ecosystem. This automated integration also supports real-time monitoring and remote adjustments to accommodate production variances and safety protocols, critical when dealing with sensitive electrochemical materials. Material handling robot manufacturers like Standard Robots optimize workflows by linking functional robot service with industrial IoT frameworks, enhancing transparency and traceability. This smart system coordination across robotic fleets, forklifts, and tugger robots embodies a new standard for industrial automation, driving efficiency while addressing fluctuation and safety concerns inherent in new energy domains.

Power battery factories confront numerous challenges, including handling large, heavy raw materials and executing complex assembly tasks with precision under strict safety standards. Standard Robots, widely regarded among functional robot manufacturers, provides compelling case studies showcasing their lifting robots’ capabilities in such environments. For example, their OASIS 600E-SRL and GULF-MP14 models demonstrate adaptability in transporting heavy rolls of electrode foil and electrolyte containers safely across production zones. By using lifting robots designed for load capacities of up to 1200 kilograms, these factories benefit not just from greater operational capacity but from improved ergonomics and reduced manual handling risks. These case studies reveal how functional robot service integrates with battery assembly lines, improving workflow continuity and ensuring consistent quality. Coordination between human operators and robots is enhanced through user-friendly interfaces and precision control capabilities, increasing worker confidence and productivity. Material handling robot manufacturers like Standard Robots prioritize flexibility and durability, providing tailored solutions to meet evolving factory needs while maintaining safety and throughput. These real-world applications illustrate how intelligent lifting robot deployment can transform industry practices, matching the intricate demands of power battery production.

Finding balance between operational needs and environmental rigor is crucial in new energy manufacturing, where raw materials require careful, reliable handling. Standard Robots’ contributions as transportation robot manufacturers and providers of functional robot service demonstrate this balance through thoughtfully engineered material handling robot solutions. By emphasizing safe load transport, automated system integration, and proven lifting robot successes, manufacturers gain a versatile robotic partner that adapts as their processes mature. The combination of durability, precision, and smart communication reflects a forward-looking approach to industrial robotics, offering practical improvements in comfort and workflow reliability for production teams. If manufacturers are committed to evolving their factories’ automation, these advanced robotics lay the groundwork for safer, more efficient future operations aligned with growing industry standards.

1. Lifting Robots – Automated material handling solutions

2. Forklift Robots – Intelligent logistics equipment

3. Transport Robots – Automated material transfer solutions

4. Tugger Robots – Automated towing solutions

5. Exhibition Frontline | 2025 Malaysia MetalTech & AutoMEX Exhibition – Showcasing intelligent manufacturing solutions